It consists of the study of the variables that affect the performance of a particular piece of equipment or an operation in general in order to generate solid proposals to improve the performance of a piece of equipment or the productivity of a process.

De este modo se facilita la tarea de identificar qué tipo de respuestas pueden ocurrir frente a determinadas situaciones, evitando la exposición al riesgo para las personas, equipos, estructuras, medio ambiente, etc.

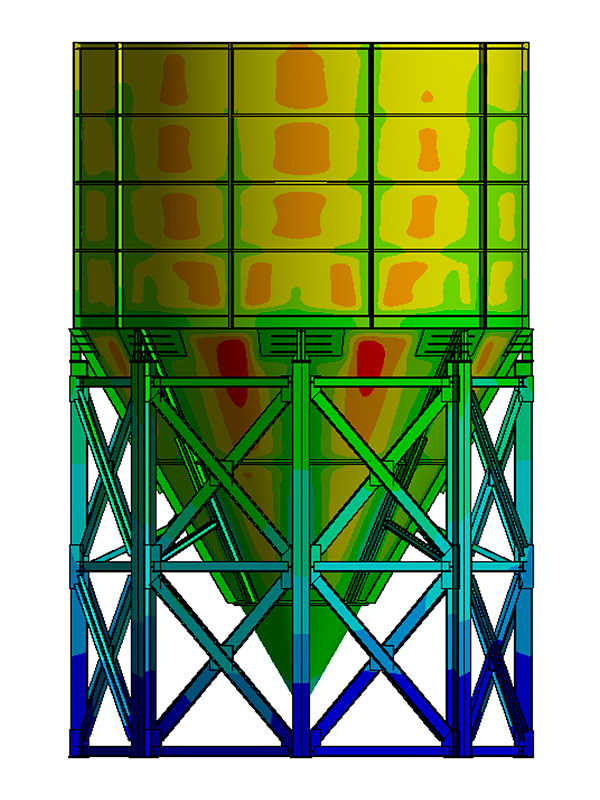

- Failure analysis of mechanical and structural equipment.

- Analysis of fluid dynamic processes, gases and ventilation.

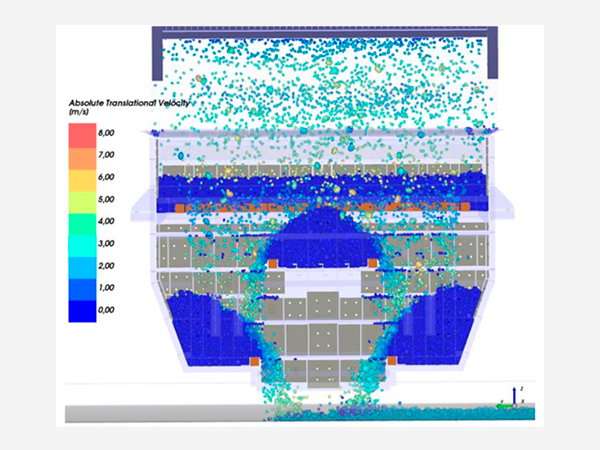

- Material handling analysis.

- Fatigue and durability analysis.

- Crack propagation analysis.

- Mechanical and structural vibration analysis.

- Equipment and process optimization.

- Trade off analysis, feasibility and pre-feasibility studies.

- Stress analysis of critical areas for inspection and maintenance.

- Wear analysis for equipment service time extension.

- Evaluation and analysis of thermal processes and equipment (fusion reactors, conversion, cooling equipment, etc).

- Analysis of circuits and networks for handling liquids, gases, pulps and tailings.