Do you know the criticality of molten salt tanks in the thermo solar plant process CERRO DOMINADOR

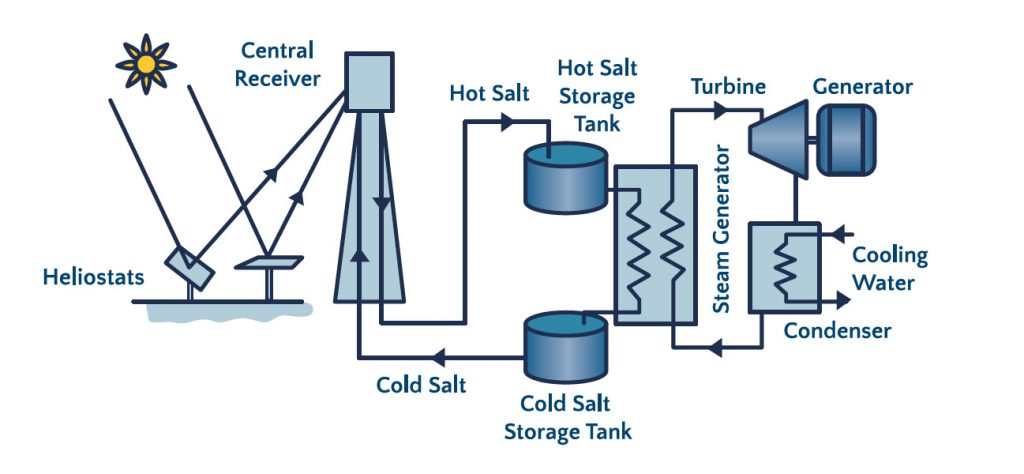

One of the great challenges of solar energy conversion systems is the continuity of electricity supply due to the absence of useful radiation during the night. Solar thermal power systems, such as a concentrating solar power (CSP) plant, do not escape this challenge. One way in which it is currently possible to solve this issue is through the use of molten salts. In this approach, a system of tanks containing salts that heat up during the day and deliver that energy at night by producing steam is designed. This is conducted to a turbine where the energy of this steam is converted into rotating mechanical energy, which is finally transformed into electricity.

The design of these molten salt systems is not without engineering challenges. The operating temperature range of these salts -which are generally a mixture of sodium nitrate (NaNO3) and potassium nitrate (KNO3)- ranges from 285°C to 565°C. Commonly, below 220°C these mixtures crystallize and above 570°C they become chemically unstable. As is evident, temperature control and the thermomechanical design of the system components is fundamental for a successful long-term operation. In this regard, if we turn our attention to the tanks that store these molten salts, questions arise that must be resolved in order to achieve a good design. For example: What size should these tanks be, how to reduce heat losses and at the same time keep the tank materials at adequate temperatures, how to design the joints -and in general the design of the tank- to resist the expansions that will occur as a consequence of the thermal gradient, considering also the conditions of the night in the desert? Is this thermal cycle safe in the long term or is there a risk of failure due to cyclic thermo-mechanical loads?

The design of these molten salt systems is not without engineering challenges. The operating temperature range of these salts -which are generally a mixture of sodium nitrate (NaNO3) and potassium nitrate (KNO3)- ranges from 285°C to 565°C. Commonly, below 220°C these mixtures crystallize and above 570°C they become chemically unstable. As is evident, temperature control and the thermomechanical design of the system components is fundamental for a successful long-term operation. In this regard, if we turn our attention to the tanks that store these molten salts, questions arise that must be resolved in order to achieve a good design. For example: What size should these tanks be, how to reduce heat losses and at the same time keep the tank materials at adequate temperatures, how to design the joints -and in general the design of the tank- to resist the expansions that will occur as a consequence of the thermal gradient, considering also the conditions of the night in the desert? Is this thermal cycle safe in the long term or is there a risk of failure due to cyclic thermo-mechanical loads?

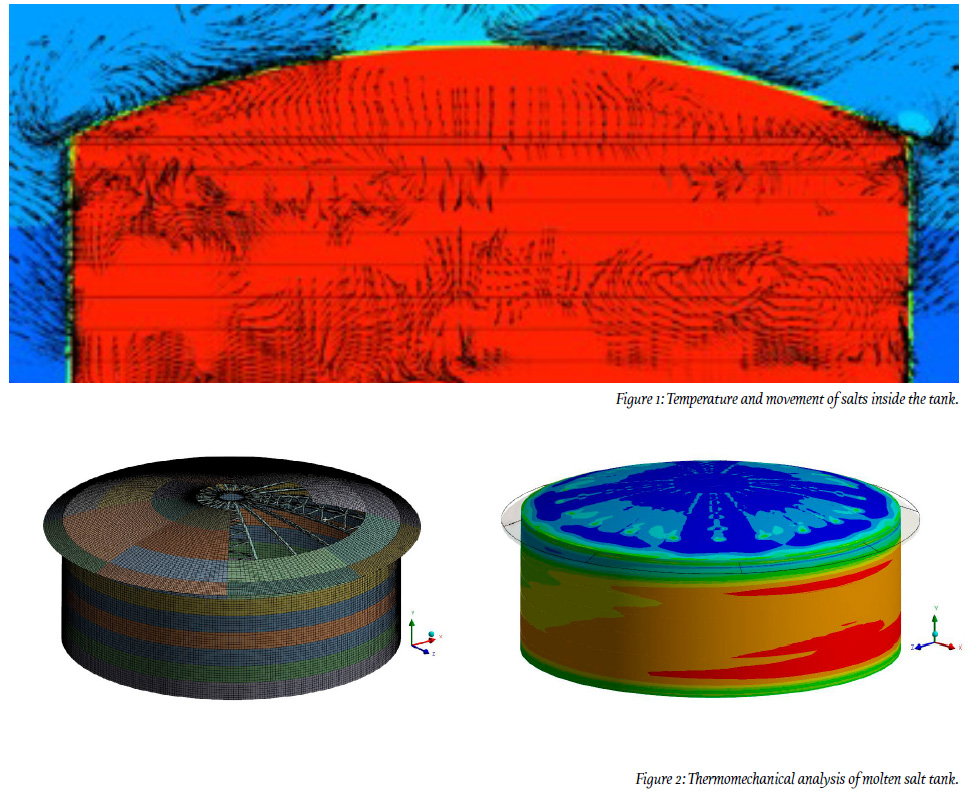

One strategy to be able to answer these questions with certainty is through the mechanical simulation tools that exist today. In them all these effects can be integrated and resolved in order to adjust the design and achieve a safer and more reliable operation. In 2014 members of the Syntec team participated in the development of a comprehensive study of the Cerro Dominador plant tanks. On that occasion, a fluid dynamic analysis of salts inside the tanks was performed (Figure 1) and coupled with a thermo-mechanical analysis (Figure 2) to study the structural integrity. The conclusions obtained allowed suggesting improvements in the initial design of the tank. For Syntec it is a great satisfaction to see the successful inauguration of this plant of such national and international connotation. From our specialized engineering studies and R&D services we will continue working to promote the ideas and innovative projects of our customers to see them move from the world of simulations to their implementation in the real world.