Backed by Specialized Engineering:

Syntec offers optimization of gas handling in foundries through applied multiphysics

The company, which in the last five years has led about 3 0 ventilation projects in foundries, guarantees full knowledge of the physics and chemistry present in the processes, and an accurate interpretation of results.

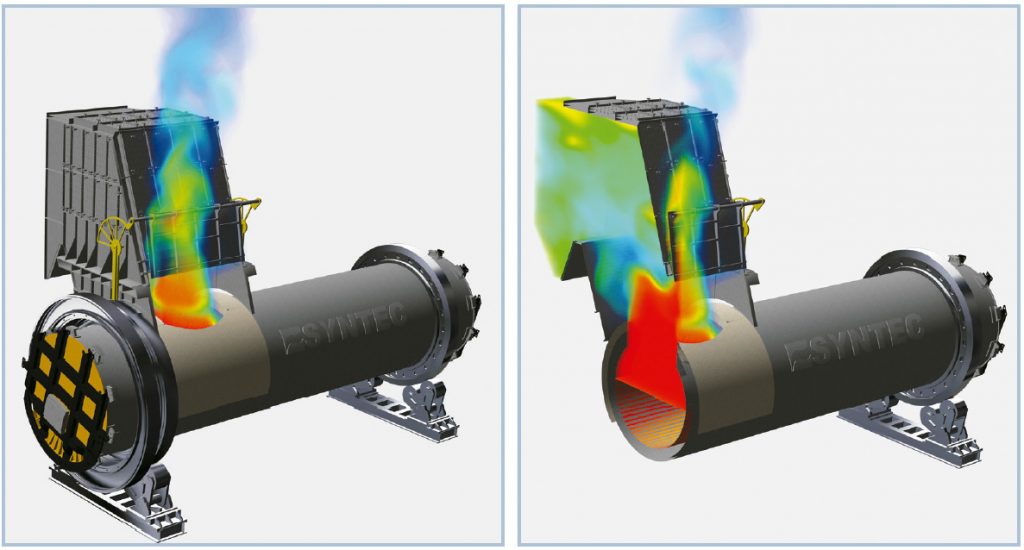

In the last five years, Syntec, a company dedicated to specialized engineering, has led around 30 projects related to ventilation and gas handling in smelting plants, offering solutions to complex problems through advanced technical studies. Máximo León, the company’s Project Manager, says that today’s mining industry is facing more and more challenges, such as low grades and more demanding regulations, requiring innovative solutions that are obtained through the use of special analysis tools. “One of them is our simulation tool, coupled with physical and chemical models, also known as Multiphysics. All this is accompanied by a broad knowledge of foundry processes and an accurate interpretation of the results,” he says.

LOWER INVESTMENT

León recalls that, until a few years ago, Chile was in the last quartile of the world ranking in terms of gas management in foundries. Then, the mining companies had to respond to the requirements of Supreme Decree 28 on gas and particulate matter emissions, which implied a high level of investment. “With our simulation tool, processes are optimized, and costs are considerably reduced, since, for example, oversizing in ducts, ventilation equipment, filter hoods, among others, is avoided,” he says.

KNOW HOW

Juan Osses, Syntec’s Research and Development Manager, explains that the smelter operates with high temperatura equipment, a necessary condition for processing the concentrate (fusion, conversion, or refining) which, in addition, must have certain mineralogical input characteristics. “This produces reactions, hot gases and particulate material with arsenic content that emanate from the furnaces and converters, so they must be guided and filtered with treatments that prevent contamination,” he points out. For Osses, physics and chemistry must be understood when addressing these matters. “High-temperature gases transmit heat by radiation. In addition, there are gas handling systems that have combustion systems, required to eliminate waste. Added to the above is the effect of the separation between the emission zone and the capture zone, which is influenced by wind effects. All these elements can be analyzed in a single simulation that includes physical-chemical effects, which depend on the particular characteristics of the gas handling system of each plant”. He adds that “to obtain data that can later be used to redesign or solve a problem, the simulation and consultancy offered by Syntec is necessary”.

IN CHILE AND THE WORLD

León affirms that there are few companies in Chile and the world that, in addition to knowing how to operate software and high technology, have as much knowledge about gas management as Syntec. “This is our added value and what has allowed us to internationalize our services, consolidating us as a validated player to meet this demand in the global market,” he says. He says that the firm has the technical capacity to respond to emergencies that occur in the plants. “We are an alternative that allows the client to gain in time, cost and quality,” he concludes.

Validity in Mining

Simulation tools have achieved full validity in mining. So says Juan Osses, Research and Development Manager at Syntec, who recalls that “they were created by the automotive and aerospace industries in the last century. However, in the last decade they began to be used intensively in the mining industry, given the complexity of copper production processes involving energy, heat transfers, interacting phases, reactions and particle and gas emissions”. “In addition to being a tool that serves for the design and development of a project, it also allows us to demonstrate to the authorities that the commitments will indeed be fulfilled,” he concludes. Syntec has the following computational simulation and geometric surveying tools:

- Ansys mechanical

- Rocky DEM

- Ansys fluent

- Faro Focus

- Ansys cfx

- Leica BLC360

- Solidworks

- Open Foam

- Caesar II

- Paraview

- Matlab & Simulink