Syntec expands its service offering with the acquisition of a new tool

The cross-check of the results allows transferring more reliability and accuracy to the client.

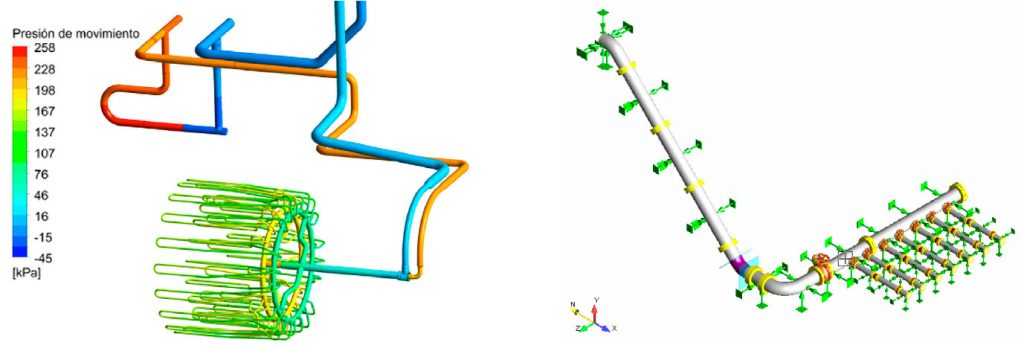

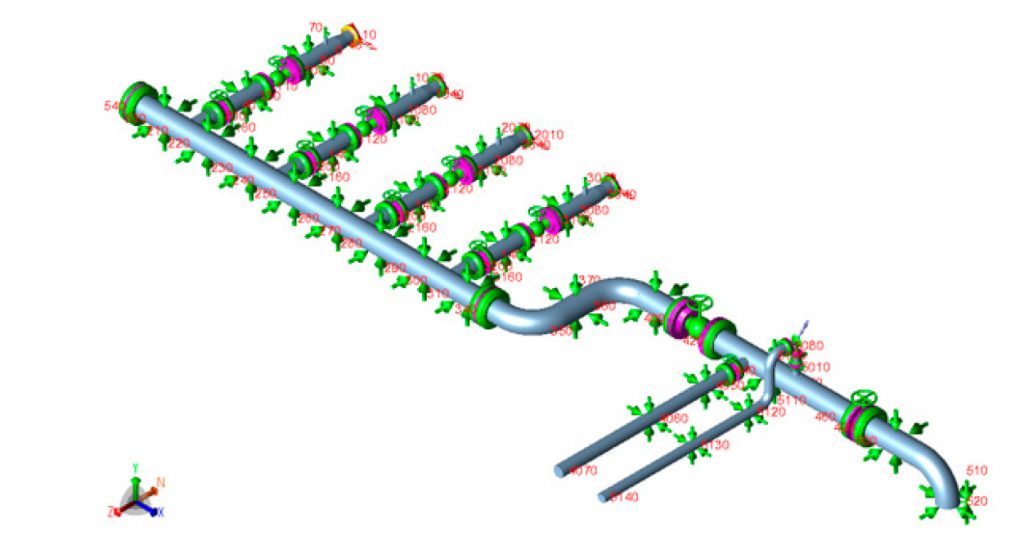

Specialized studies in fluid transport are part of the new service provided by the specialized engineering consulting company Syntec. CAESAR II, the software recently acquired by the firm, has the capacity to perform flexibility and stress analysis of pipes of different materials and under different installation conditions. (Surface and underground pipelines). Likewise, the software can analyze various fluids, such as: water, tailings, oil and especially those of greater complexity due to their high temperature, as is the case of vapors. The specific function of this tool is to verify if the pipes and equipment connected to them can withstand sustained and occasional operational loads, such as temperature, high pressure, wind, snow, earthquakes, among others. The results of this study allow to determine if a redesign of the pipeline support system is required.

In a multidisciplinary engineering project, the Mechanical and Piping section is always considered because of the relevance of these pipelines in the operation of plants in a wide variety of industries. However, analyzing how a complex system behaves when faced with combinations of loads of different nature -including in some cases “punctual events”- is part of what only a specialized engineering consultancy can deliver. Caesar II has various international piping standards such as ASME B31B, B31.4, etc. configured. With this database it is possible to accurately check compliance with these important standards prior to operation. It should be noted that the software updates the new versions of the aforementioned standards in a timely manner, in order to guarantee their validity.

Another transcendental aspect resulting from the studies that can be carried out with this tool is that it provides a verification of the appropriate loads at the connection points to the equipment. A good example of this is pumps. This process is carried out at the detailed engineering stage, that is, when the equipment is already installed. In summary, the integrity of the pipelines and the capital equipment connected to them is studied. Likewise, the suitability of specific parts that are key to the reliability of the pipeline operation can be analyzed and verified, such as valves, couplings and supports, as well as estimating the number of years of useful life that a pipeline will have.

All the aforementioned analyses result in a shorter response time for the client and greater certainty and accuracy of the deliverables provided by Syntec, since the data collected from CAESAR II are compatible with the studies coming from other tools widely mastered by the experts of our company, such as Ansys Mechanical, Ansys Fluent, Ansys CFX and Rocky DEM, among others. This provides the great advantage of increasing the reliability of the solutions provided thanks to the accuracy of results coming from different sources that are subjected to a contrast or cross check for final ratification.