Client

WOOD

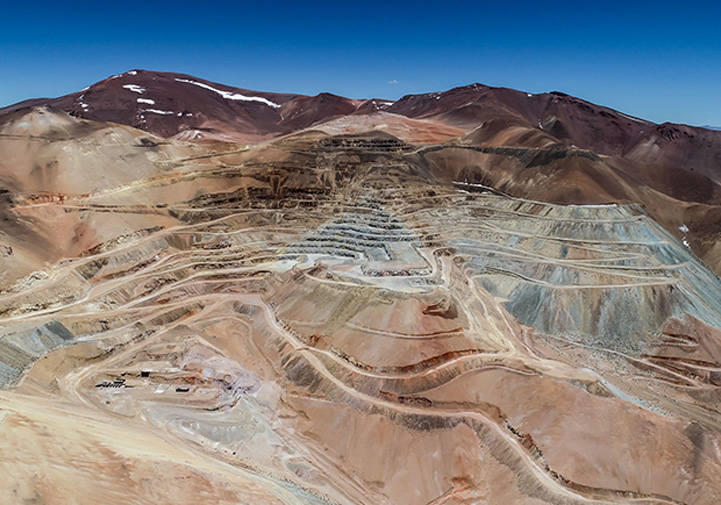

Project

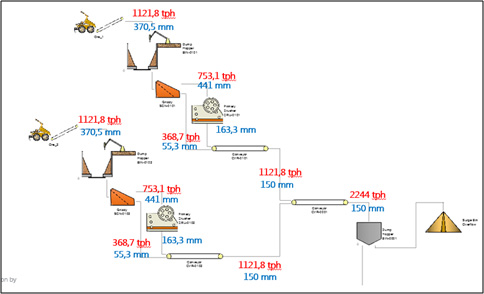

2645 - Kinross Lobo-Marte Project Concentrator Plant Dynamic Simulation

Problem

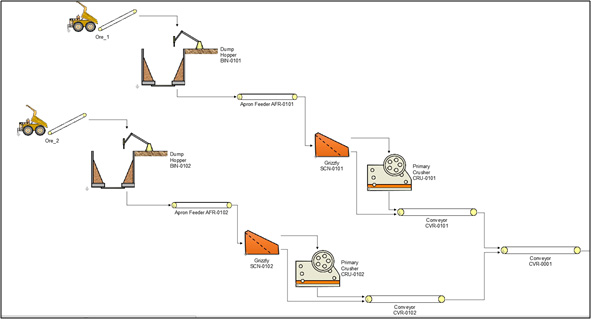

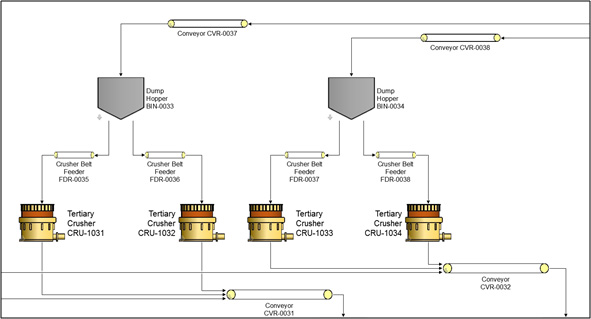

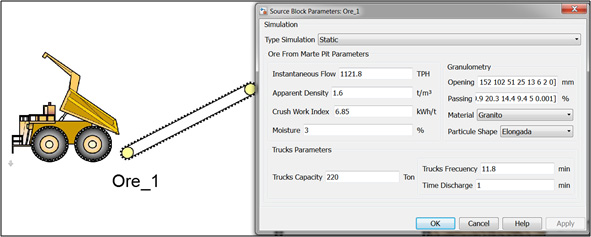

Determine capacities, identify bottlenecks and clearances in material handling, considering availability established in the basic engineering in order to establish the process engineering design criteria for the Lobo-Marte gold project Feasibility Study.

Solution

Through dynamic simulation of the concentrator plant process, programming developed in Matlab Simulink was designed to standardize the behavior of the plant process, considering the simplified logic of control, balances (mass, water, and energy) and material handling. This allowed to assess possible scenarios modifying criteria or lines of the process and thus permitting the optimal operation of the plant.

Improvement

The main bottlenecks generated by the original design of the process plant were resolved. In addition, future design changes and their approval for feasibility engineering advances are determined.

See more success stories:

- Improvement and Redesign of Fluid Dynamic Processes

- Engineering for Operational Continuity Based on 3D Scanner Survey

- Study for Vertical Mill Maintenability

- Transfer Point Redesign (Chute Case)

- Structural/Mechanical Diagnosis and Vibration Study for a Bucket Wheel

- Device for Aerodynamic Drag Reduction in Heavy Ground Transportation