Client

CODELCO – División Ministro Hales (DMH)

Project

1524, 1545, 1553 and 1896 – Study of the Cooling Tower in different stages.

Issues

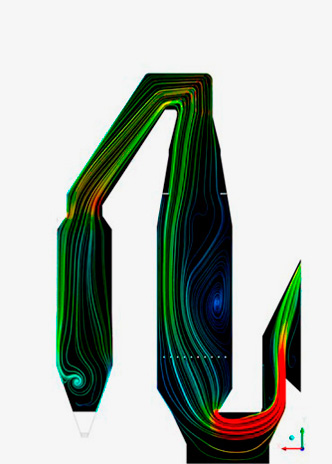

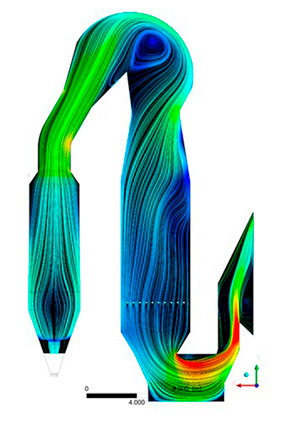

The water injected into the Cooling Tower (CT) does not evaporate completely, reaching the Dry Electrostatic Precipitator (DEP) in liquid form, affecting the performance of the latter.

Solution

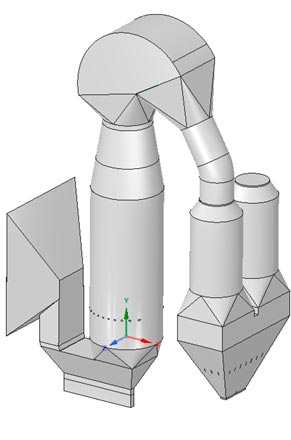

Through a fluid dynamic analysis of the CT, supported by computational fluid dynamic (CFD) simulation, problems in the flow distribution generated by the upper part of the CT are detected, as well as problems in the cooling water injection. Once detected, the upper part is redesigned and the cooling water injection system is improved, supported by the CFD tool.

Improvement

Increased cooling efficiency of the tower, decreased internal corrosion of the tower, decreased formation of slime in the CT, decreased formation of accretions in the ESP fields, and increased useful life of the ESP fields. In addition to the above, the solution provided by Syntec contributes to operational continuity and a decrease in the accident rate of the plant due to a longer time between maintenance.

See more success stories:

- Improvement and Redesign of Fluid Dynamic Processes

- Engineering for Operational Continuity Based on 3D Scanner Survey

- Study for Vertical Mill Maintenability

- Transfer Point Redesign (Chute Case)

- Structural/Mechanical Diagnosis and Vibration Study for a Bucket Wheel

- Device for Aerodynamic Drag Reduction in Heavy Ground Transportation