Client

AngloAmerican - Los Bronces

Project

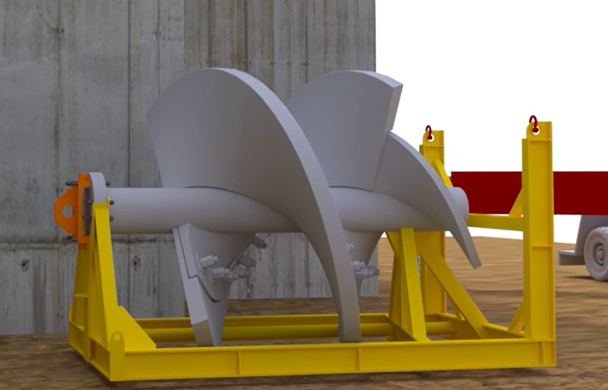

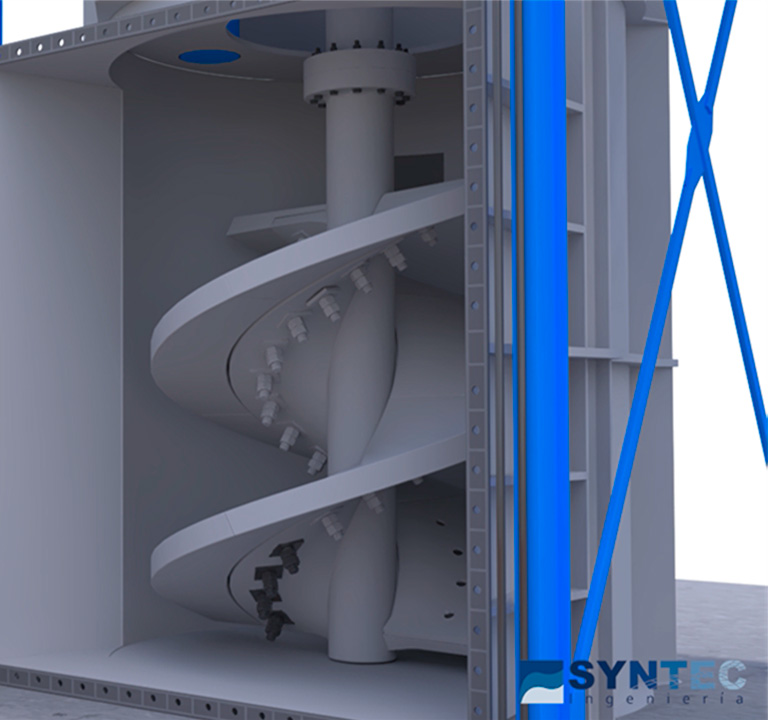

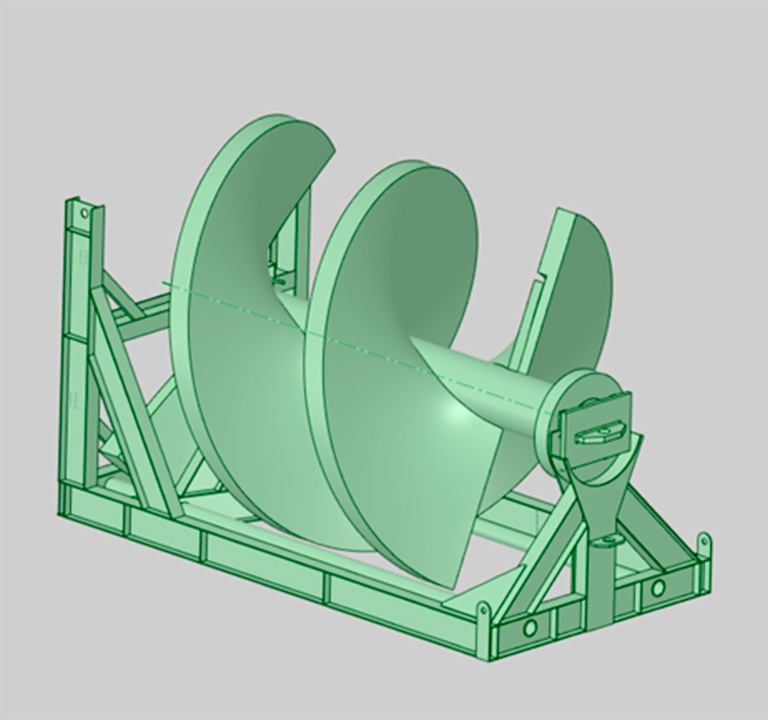

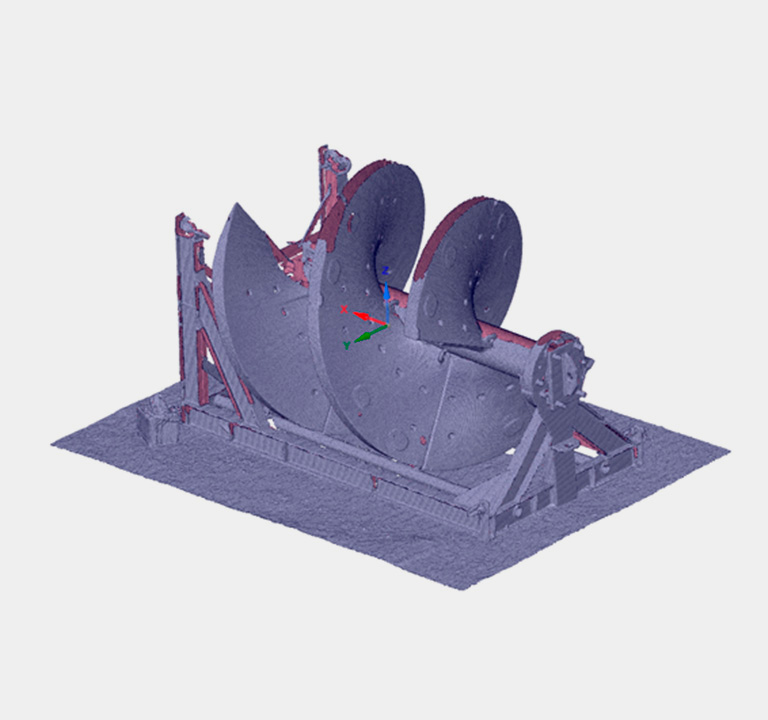

1963 – Vertimill LT Mill Screw Change Animation

Issue

Describe in detail –through 3D Animation- an optimal maintenance and worm gear change procedure of a vertical mill.

Solution

Through field observer criteria, a clearer maintenance strategy for capital equipment can be defined, which impacts on a decrease of effective hours in terms of the complete maneuver including the change of worm gear of a vertical mill.

Improvement

Considering this reduction in plant downtime hour, the solution provided by Syntec contributes to operational continuity and supports the reduction in the accident rate of those involved in this maneuver, given the precision and clarity of the instructions of the audiovisual material provided.

Vertical Mill Screw Change Maintenance Procedure

See more success stories:

- Improvement and Redesign of Fluid Dynamic Processes

- Engineering for Operational Continuity Based on 3D Scanner Survey

- Study for Vertical Mill Maintenability

- Transfer Point Redesign (Chute Case)

- Structural/Mechanical Diagnosis and Vibration Study for a Bucket Wheel

- Device for Aerodynamic Drag Reduction in Heavy Ground Transportation